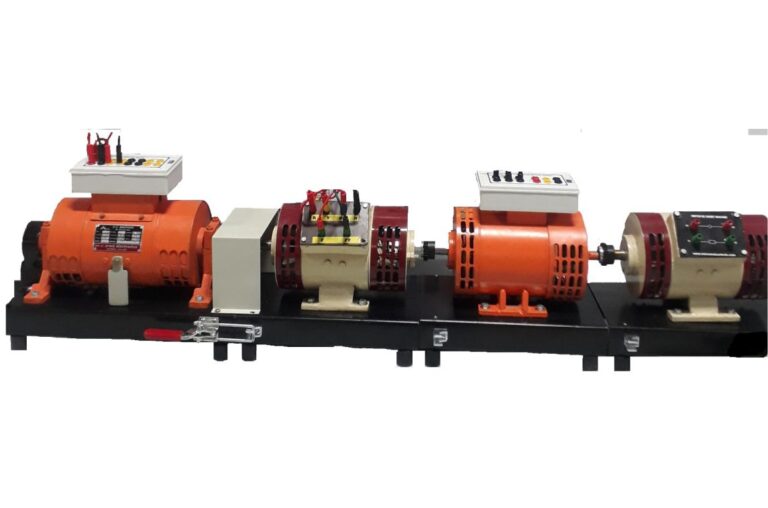

ELECTRICAL MACHINE TRAINER

Salient Features:

- Facilitates easy & safe wiring by students due to 4 mm sturdy shrouded banana patch Cords.

- Provided Short circuit and overload protection using Fuse/ MCB/CB/OL thermal relay.

- Included Earth socket on control Trainer from student’s safety point of view.

- The components fitted on the Panel are labelled with the name of the component.

- All components are connected with internal wiring and provision for external wiring using shockproof patch cords.

- Provided set of Instructor Guide & Student Workbook.

- MS/ABS molded plastic sturdy enclosure & rust-free powder coated control panel.

- Modular Panel with Colorful overlays showing circuit diagram & its connection tag numbers for easy understanding, connections & servicing by swapping at site.

- MS/Aluminum profile sturdy flat panel (table top) system, carrying various high voltage components housed in plastic enclosures (panel) to minimize shock possibility.

- Modular, multi machine/motor, multi experiment training system useful for visualizing & demonstrating the construction and functioning of different types of (Single phase and three phase) DC and AC Machines.

- Trunnion mounted DC Integrated machine is used as Dynamometer for loading other machines (Motors / generators both), with facility to measure shaft power using electronic torque / speed measurement.

- All machines are mounted on finely painted sturdy base frame with easy machine interchangeability, Use of screw less gear coupling/Love –Joy coupling facilitates.

Control Panel Technical Specifications:

EE1 – Three phase Power Supply panel:

- MCB 4 pole, 4 Amp, 415V AC, 50Hz.

- RYB power input Indicator (22 mm) x 3 Nos.

- Volt meter 415V AC ( 72x72mm)

EE2 – Three Phase DOL Starter panel:

- Contactor 9 Amp. 415V, 50 Hz, 3 Pole, 1 NO.

- Contactor Coil: 230V, 11VA.

- Bimetallic over load thermal Relay.

- Relay Range 1.4A – 2.3A. (Set: 2.3 Amp.)

- Start-Stop Push Button Switch.

- DOL ON Red Indicator (22mm

EE3 A/B/C – Multi-function Bi-directional Power Measurement Panel (2 nos.):

- Digital Bi-directional Multi-function meter (96X96mm).

- 3 Phase 3/4 wire, Voltage line to line & line to neutral.

- Measurement of 415V, 3 ph. & 230V, 1 ph. parameters.

- Measures V, I, Hz, PF, KW, KVA, KVAr, Energy in KWh.

- Current for all 3 ph. up to 5A. (Inbuilt CT 5A:5A x 3 Nos.)

- LCD/LED display, Reverse Power Indication.

- Supply 230VAC, 45-65Hz, 5W

- Optionally PC interface with RS485 (Power Analyzer)

EE4 – FWD/REV, Manual Star- Delta Starter panel:

- Three Ph. ON-OFF-ON with FWD/REV, 3 pole 3 way switch with center OFF, 6A/440V.

- Star/Delta switch 3 pole, 3 way with Centre OFF, 6A/440V.

- Starter ON & Power ON Red Indicator (22 mm each)

EE5 – ON OFF ON, FWD/REV Panel:

- Three Ph. ON-OFF-ON with FWD/REV, 3 pole 3 way switch with Centre OFF, 6A/440V.

- Power ON Red Indicator (22 mm)

EE6 – Rotor resistance Starter Panel:

- Selector switch, 3 pole, 7 Way. 6A/440 V.

- Rotor resistors of 30E/5A with 4 taps of 15E, 20E, 25E, 30E x 3 nos.

- DC Rotor excitation over current circuit breaker (3 Amp)

EE7 – Single phase Power Supply Panel:

- MCB 230V AC, 50Hz.1 pole/6A(3 Nos.) 1 pole/10A(1 No.)

- Output Terminals: 230V, 6 Amp.(3 Nos.) & 10 Amp.(1No)

- Red Power Indicator (22 mm), Lamp Holder.

- 8A push button switch (Simulate as centrifugal switch) & Resistor 30E/400W. (Provide if Single ph. Ind. Motor supply)

EE8 A/B/C – SCR Based DC Variable Power Supply (3 nos.)

- 230V AC Input, Output 0 to 195V DC, 5 Amp.

- Full bridge SCR based, Cosine firing with linear charateristics.

for Armature, motor field & Alternator/generator field.

EE9 – Signal conditioning Cum Display panel:

- Red Power Indicator (22 mm)

- Multi channel Digital RPM & Torque Display.

- Supports Sensor signal conditioning circuit for Speed, Torque in kg. to give output 0-2.5V DC (FS)

EE10 – DC Voltmeter & Ammeter panel:

- Voltmeter: 0 to 300V DC (72x72mm)

- Ammeter: 0 to 1A DC (72x72mm)

- Polarity protection diode.

- Circuit Breaker for over load protection.

- Field failure relay to control Armature.

EE11 A/B – DC Voltmeter & Ammeter panel (2 nos.):

- Voltmeter; 0 to 300V DC (72x72mm)

- Ammeter: 0 to 5A DC (72x72mm)

- Polarity protection diode.

- Circuit Breaker for over load protection.

EE12 – Variable AC/DC Power Supply Panel:

- 230V AC Input, 0 to 270V AC, 3Amp Output.

- Diode Bridge AC to DC, 0 to 260V DC, 3Amp. Output

- Full bridge Diode based.

EE13 – Single Phase AC/DC Resistive(R) Load Panel:

- Selector switch, 2 pole, 7 Way. 10A/440 V.

- Resistors 750E-600E-300E-212E-162E-100E-OFF. 400W / 7 Steps.

- Separate 60E tap for DC series Gen. (if DC Series Gen. Supply)

EE14 – Three Phase Resistive(R) Load Panel:

- Selector switch, 3 phase, 3 pole, 7 Way, 10A/440 V.

- Resistors 10K-5K-3.5K-2.5K-2K-1.5K-OFF/200W, 7 Steps.

EE15 – Inductive (L) Load Panel:

- Selector switch, 3 phase, 3 pole, 7 Way. 10A/440 V.

- Inductors: 0.15H-0.3H-0.45H-0.6H-0.75H-1.5H-3H/400 mA, 7 Steps.

EE16 – Capacitive (C) Load Panel:

- Selector switch, 1 Ph/3 phase, 3 pole, 7 Way. 10A/440 V.

Capacitive load =1mf-2mf-2.5mf-4mf-5mf-6mf-OFF, 7 Steps.

EE17 – Synchronizing/Paralleling Panel (Optional):

- Synchroscope with LED Indications.

- Three Lamps for Lamp Method experiment.

- Synchronizing Switch, Synchroscope ON-OFF switch.

Accessories :

Patch Cord,

Manual,

Dust Cover.

PC Interface & Software for data Acquisition (Optional):

- Data Acquisition using Modbus Serial RTU.

- Data Acquisition from Analog interface unit.

- Speed, torque,

- Voltages, currents,

- Frequency,

- Operating efficiency,

- Active power

- Reactive power

- Power factor,

- Calculated torque and slip etc.

3. App has facility to monitor online data as DPM as well as Charts.

- Also can save data in PDF or Excel data as per student identification (Roll no., Name) also charts can be saved as Image file.

- Has facility to copy data to Removable device

- Application based Dual Arm® Cortex®-A72 microprocessor subsystem @ 2GHz with 7” LCD HDMI device

- USB /Serial interface, keyboard mouse.

Motor, Generator & Alternator Technical Specifications:-

Machine No. 1 – DC Integrated Machine – Trunnion mount, Dynamo type with torque & speed sensors.

Note: Machine Sr. No. 1 is Compulsory & following other machines are optional.

Volt: 180V Arm. & Field, HP: 0.5HP /2 Pole RPM: 1500RPM, Terminals: 6

Rotor: Standard commutator / brush arrangement with laminated stack, brought out on 2 terminals

Stator: Separately excited field winding with laminated solid yoke 2 pole and series winding brought out on 4 terminals.

Experiments List: I) Motors: Speed torque curves of a) Shunt motor, b) DC series motor, c) Separately excited DC motor d) DC compound motor (Cumulative & Differential)

II) Generator (Needs to be driven): V-I & Efficiency curves for –

a) DC Shunt generator b) DC series generator c) DC separately excited generator d) DC compound generator.

IV) Efficiency: All above type DC m/c.

Winding Temp: Embedded Thermistor brought out on 2 eyelets mounted on terminal box for monitoring winding temperature.

Frame: 90, Shaft dia: 19 mm,

Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 45 Kg., Gross: 65 Kg.

Machine No. 2 – DC Motor/Generator (Optional with Above Machine No .1)

Volt: 180V Arm. & Field, HP: 0.5HP /2 Pole RPM: 1500RPM, Terminals: 6

Rotor: Standard commutator / brush arrangement with laminated stack, brought out on 2 terminals.

Stator: Separately excited field winding with laminated solid yoke 2 pole and series winding brought out on 4 terminals.

Experiments List: I) Motors: Speed torque curves of –

- a) Shunt motor, b) DC series motor, c) Separately excited DC motor d) DC compound motor (Cumulative & Differential)

- II) Generator: V-I & Efficiency curves for a) DC Shunt generator

- b) DC series generator c) DC separately excited generator

- d) DC compound generator.

- IV) Efficiency: All above DC m/c. (V, VI, VII) ?

- V) Swin burn’s test: Measurement of NO load losses to determine efficiency of DC shunt motor.

- VI) Hopkinson’s test: Back to back test on two identical DC shunt m/cs. (Needs 2 nos. of DC m/c to be coupled to each other)

Winding Temp: Embedded Thermistor brought out on 2 eyelets mounted on terminal box for monitoring winding temperature.

Frame: 90, Shaft dia: 19 mm, Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 38 Kg., Gross: 57 Kg.

Machine No. 3 – Single phase AC Cap. Start & Cap. Run Induction Motor. (Optional with Above Machine No .1)

Volt: 230VAC, 50Hz, HP: 0.5HP /4 Pole RPM: 1460, Terminals: 10

Rotor: Die-cast Squirrel cage.

Stator: Two windings brought out on 4 terminals for main & auxiliary these will be used to configure different motors split phase, CSCR CSIR.

Experiments List: Speed torque curves & Efficiency of –

- a) Split phase ind. motor, b) CSIR, Motor c) CSCR Motor.

Winding Temp: Embedded Thermistor brought out on 2 eyelets mounted on terminal box for monitoring winding temperature.

Frame: 90, Shaft dia: 19 mm, Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 38 Kg., Gross: 57 Kg.

Machine No. 4 – Repulsion Motor (Optional with Above Machine No .1)

Volt: 230VAC, 50Hz, HP: 0.5HP /4 Pole RPM: 1500, Terminals: 2

Rotor: Standard commutator Brush but short circuited.

Stator: Stator brought out on 2 terminals settable handle to rotate brush position w.r.t Neutral axis.

Experiments List: a) Speed torque curves,

- b) Speed control & reversal with brush setting using handle to rotate brush position w.r.t Neutral axis.

Winding Temp: Embedded Thermistor brought out on 2 eyelets mounted on terminal box for monitoring winding temperature.

Frame: 90, Shaft dia: 19 mm, Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 38 Kg., Gross: 57 Kg.

Machine No. 5 – Universal (AC/DC) Motor

(Optional with Above Machine No .1)

Volt: 230VAC/150V DC 50Hz, HP: 0.5HP /4 Pole RPM: 1600/1500, Terminals: 4

Rotor: Standard commutator Brush arrangement brought out on 2 terminals.

Stator: Stator brought out on 2 terminals to facilitate AC/DC operation & direction change Built in compensating winding to minimize AR & sparking.

Experiments List: Speed torque curves of universal Motor when operated with a) 220/240V AC, b) 150 V DC

Winding Temp: Embedded Thermistor brought out on 2 eyelets mounted on terminal box for monitoring winding temperature.

Frame: 90, Shaft dia: 19 mm, Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 38 Kg., Gross: 57 Kg.

Machine No. 6 – Three Phase Alternator (Optional with Above Machine No .1)

Volt: 415VAC, 50Hz, VA: 300 /4 Pole, RPM: 1500, Terminals: 6

Rotor: Star connected 4 terminal including star point brought out on 4 slip rings mounted on shaft.

Stator: Separately excited field winding with laminated solid Yoke, 4 pole brought out on 2 terminals.

Experiments List:

1) Regulation of 3 phase alternator by – i) Synchronous Impedance Method, ii) ZPF or POTIER Method, iii) Actual Load Test.

2) Determination of sequence components Z0, Z1, Z2

3) Direct axis and Quadrature axis sub transient reactance Xd” & Xq”

4) Zero sequence reactance X0

5) Negative sequence reactance X2

Winding Temp: Embedded Thermistor brought out on 2 eyelets mounted on terminal box for monitoring winding temperature.

Frame: 90, Shaft dia: 19 mm, Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 38 Kg., Gross: 57 Kg.

Machine No. 7 – Three Phase Synchronous Motor(Optional with Above Machine No .1)

Volt: 415VAC, 50Hz, VA: 300 /4 Pole, RPM: 1500, Terminals: 5

Rotor: Star connected 3 terminals brought out on 4 slip rings mounted on shaft.

Stator: Separately excited field winding with laminated solid Yoke, 4 pole brought out on 2 terminals.

Experiments List:

1) Speed torque curves of Synchronous motor.

2) Efficiency & input power factor measurement.

3) Use of synchronous motor as power factor improvement device.

4) Study of V-curve & inverted ‘V’ curve.

Winding Temp: Embedded Thermistor brought out on 2 eyelets mounted on terminal box for monitoring winding temperature.

Frame: 90, Shaft dia: 19 mm, Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 38 Kg., Gross: 57 Kg.

Machine No. 8 – Three Phase Slip Ring Induction Motor (Optional with Above Machine No .1)

Volt: 415VAC, 50Hz, HP: 0.5/4 Pole m/c, RPM: 1500, Terminals: 9

Rotor: Star connected 3 terminals brought out on slip rings mounted on shaft.

Stator: brought out on 6 terminals.

Experiments List: a) Speed torque curves of wound rotor induction motor with rotor shorted & with different rotor resistors.

- b) Efficiency measurement.

- c) DOL / Star-delta starter, rotor resistance starer.

Winding Temp: Embedded Thermistor brought out on 2 eyelets mounted on terminal box for monitoring winding temperature.

Frame: 90, Shaft dia: 19 mm, Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 38 Kg., Gross: 57 Kg

Machine No. 9 – Three Phase Squirrel Cage Induction Motor (Optional with Above Machine No .1)

Volt: 415VAC, 50Hz, HP: 0.5 /4 Pole, RPM: 1460, Terminals: 3 (6 terminal Optional)

Rotor: Die-cast Squirrel cage rotor.

Experiments List:

- a) Speed torque curves of squirrel cage rotor induction motor.

- b) DOL starter.

- c) Efficiency of 3 phase AC Squirrel cage motor.

Winding Temp: Embedded Thermistor brought out on 2 eyelets mounted on terminal box for monitoring winding temperature.

Frame: 90, Shaft dia: 19 mm, Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 38 Kg., Gross: 57 Kg.

Machine No. 10 – Three Phase Dahellander Winding Squirrel Cage Induction Motor (Optional with Above Machine No .1)

Volt: 415VAC, 50Hz, HP: 0.5 /4 Pole RPM: 1500/3000, Terminals: 6

Rotor: Die-cast Squirrel cage rotor.

Stator: 6 terminals brought out to run machine at two speeds using pole changing method (Dahellander Winding)

Experiments List:

- a) Speed torque curves of sq. cage rotor induction motor at two speeds,

- b) DOL stator.

c] Efficiency of 3 phase AC Squirrel cage motor.

Winding Temp: Embedded Thermistor brought out on 2 eyelets mounted on terminal box for monitoring winding temperature.

Frame: 90, Shaft dia: 19 mm, Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 38 Kg., Gross: 57 Kg.

Machine No. 11 – Shaded Pole Motor (Optional)

Volt: 230VAC, 50Hz, KW: 50W, 35F, RPM: 1400, Terminals: 2

Experiments List: Speed torque curves.

Frame: 35, Shaft dia: 14 mm, Mounting: Chassis mounted with spring balance brake pulley arrangement. Weight Net: 38 Kg., Gross: 57 Kg

Machine No. 12 – Eddy current Brake (Optional with Above Machine No .1)

Volt: 45V DC, Current: 3A, Power: 400W, Terminals: 2 nos.

Frame: 90, Shaft dia: 14 mm, Mounting: Chassis mounted with easily swappable gear coupling. Weight Net: 45 Kg., Gross: 65 Kg.